Revolutionizing Baking: Leveraging PLA2 for Enhanced Quality, Shelf Life, and Consumer Appeal in Bread and Cake Production

Explore how NAGASE’s phospholipase A2 (PLA2) enzyme is revolutionizing baking practices, enhancing product quality, shelf life, and consumer appeal for bread and cake producers, from large-scale manufacturers to artisanal shops.

The baking industry thrives on delivering fresh, high-quality products. However, numerous challenges present roadblocks for this seemingly simple objective. From maintaining optimal dough properties to ensuring exceptional shelf life, bakers of all sizes grapple with complexities that impact both production efficiency and consumer satisfaction. Let's delve into two key areas of concern: dough handling difficulties and limited shelf life for baked goods.

A. Dough and Batter Handling Difficulties

- Poor Extensibility: Achieving optimal dough extensibility is crucial for shaping and processing. Weak doughs resist stretching, leading to tearing, uneven bake, and inconsistent product quality. This is particularly problematic for artisan and specialty breads, where intricate shaping techniques are employed.

- Excessive Stickiness: Sticky dough presents significant challenges during processing. It adThe baking industry thrives on delivering fresh, high-quality products. However, numerous challenges present roadblocks for this seemingly simple objective. From maintaining optimal dough properties to ensuring exceptional shelf life, bakers of all sizes grapple with complexities that impact both production efficiency and consumer satisfaction. Let's delve into two key areas of concern: dough handling difficulties and limited shelf life for baked goods.heres to equipment, hindering workability and increasing production time. For large-scale industrial bakeries, this translates to reduced output and potential machinery damage.

- Shrinkage & Moisture Loss: Excessive moisture loss contributes to shrinkage and diminished product volume. This is an important concern for commercially prepared cakes and industrial breads, where maintaining consistent size and shape is essential for brand image and consumer expectation

B. Limited Shelf Life

- Staling & Gumminess: The staling process, triggered by starch retrogradation, leads to undesirable hardening and loss of freshness. This negatively affects both bread and cake products, impacting consumer perception and reducing marketability. Gumminess can further exacerbate the issue, creating an unpleasant chewing texture.

- Compromised Softness: Loss of softness after baking significantly impacts consumer appeal. Stale, crumbly textures often result from gluten interactions during storage, leading to decreased sales and potential product waste.

These recurring challenges in dough handling and shelf life pose significant obstacles for all segments of the baking industry. The quest for solutions that improve dough workability, enhance product softness, extend shelf life, and optimize production efficiency remains a constant pursuit. It is within this context that innovative ingredients like NAGASE PLA2 enzyme offer enticing possibilities, potentially revolutionizing baking practices and delivering tangible benefits to bakers of all scales.

NAGASE PLA2 Enzyme

NAGASE PLA2 Enzyme is a natural enzymatic powerhouse found in various organisms, including grains, specifically targeting the lecithin present in egg yolks. This microbial phospholipase A2 modifies dough behavior at a fundamental level, improving emulsifying properties and resulting in enhanced extensibility, reduced stickiness, and extended softness. Unlike animal-derived enzymes, NAGASE PLA2 offers a vegan-friendly, solution for bakers, providing improved dough handling and shelf-life benefits. Its precise targeting of egg yolk lecithin ensures demonstrably enhanced dough characteristics, empowering bakers to achieve superior shaping, simplify processing, and deliver consistently delightful textures. With kosher and halal certifications, NAGASE PLA2 also complies with dietary restrictions, making it a versatile solution within the baking industry.

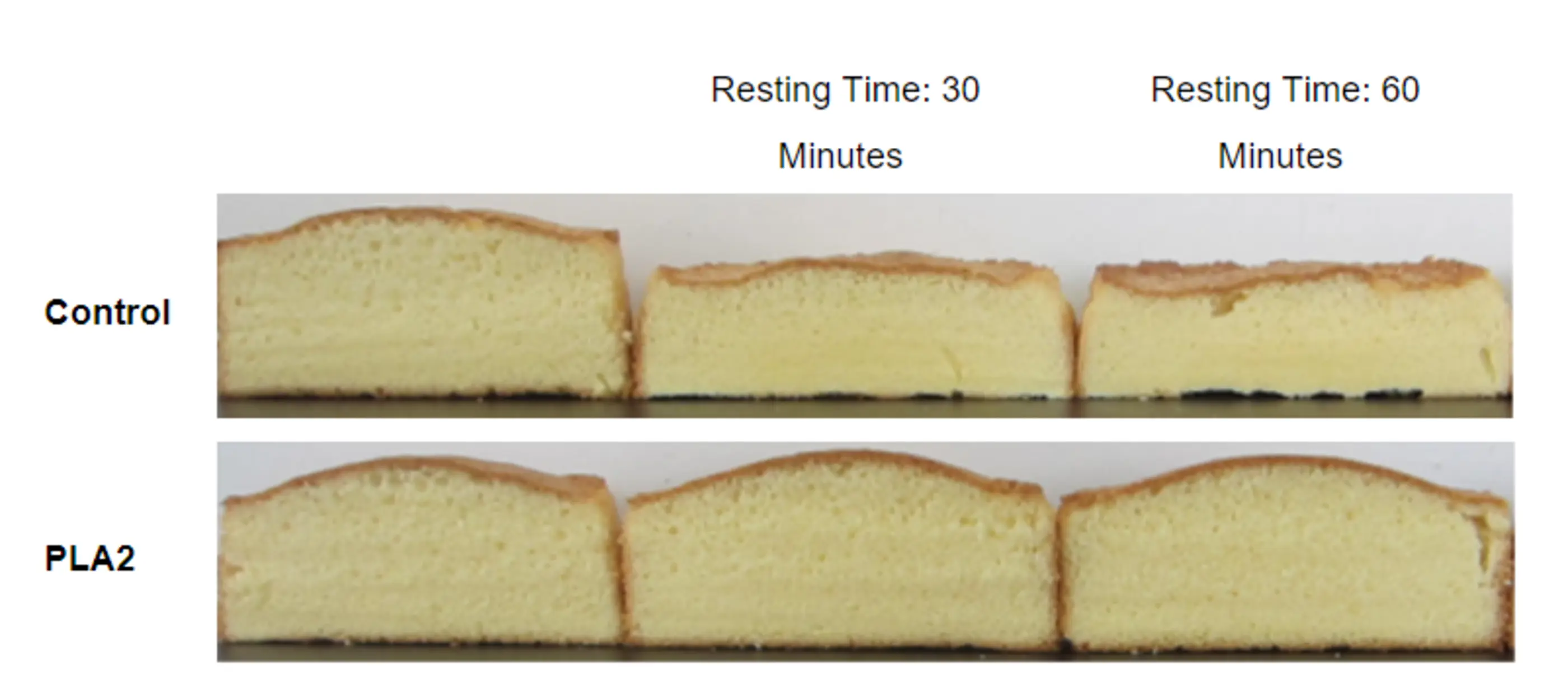

To empirically validate the claims regarding PLA2's ability to stabilize cake batter, minimize baking shrinkage, and maintain consistent product volume, a controlled baking experiment was conducted. Two identical batches of batter were prepared, mirroring a standard recipe. However, one batch was enriched with a pre-determined dosage of PLA2, while the other served as a control without the enzyme. To isolate the influence of PLA2 on post-baking stability, each batch was further divided into three parts:

Fresh: Baked immediately after mixing, representing baseline volume and structure.

30-minute rest: Baked after resting for 30 minutes, simulating typical bakery workflows.

60-minute rest: Baked after resting for 60 minutes, pushing the boundaries of pre-baking delay.

The results demonstrated PLA2's potent impact on volume retention through the following observations:

- Immediate Baking

- Both control and experimental batches exhibited similar cake volumes.

- 30-Minute Resting Period

- Control Batch: Decreased volume and poor cake structure.

- Experimental Batch (with PLA2): Maintained volume and improved cake structure.

- 60-Minute Resting Period

- Control Batch: Further decrease in volume and compromised cake structure.

- Experimental Batch (with PLA2): Sustained volume and superior cake structure.

The observed differences in cake volume and structure between the various batches after resting periods provide valuable insights into the benefits of PLA2 in sponge cake preparation. During the 30-minute and 60-minute resting periods, the control batch exhibited reduced volume and poor cake structure, indicating a breakdown in stability. In contrast, the PLA2 batch maintained better emulsification, preventing degradation of the batter during resting. PLA2 plays a role in stabilizing batter for sponge cakes. It functions by breaking down phospholipids present in the flour and egg yolk. The breakdown of phospholipids results in the generation of lysophospholipids, which can interact with fats and water in the batter. PLA2 helps in emulsifying the fat, which means it disperses fat evenly throughout the batter. This emulsification contributes to a more uniform texture and aeration in the cake.

Egg Reduction with PLA2

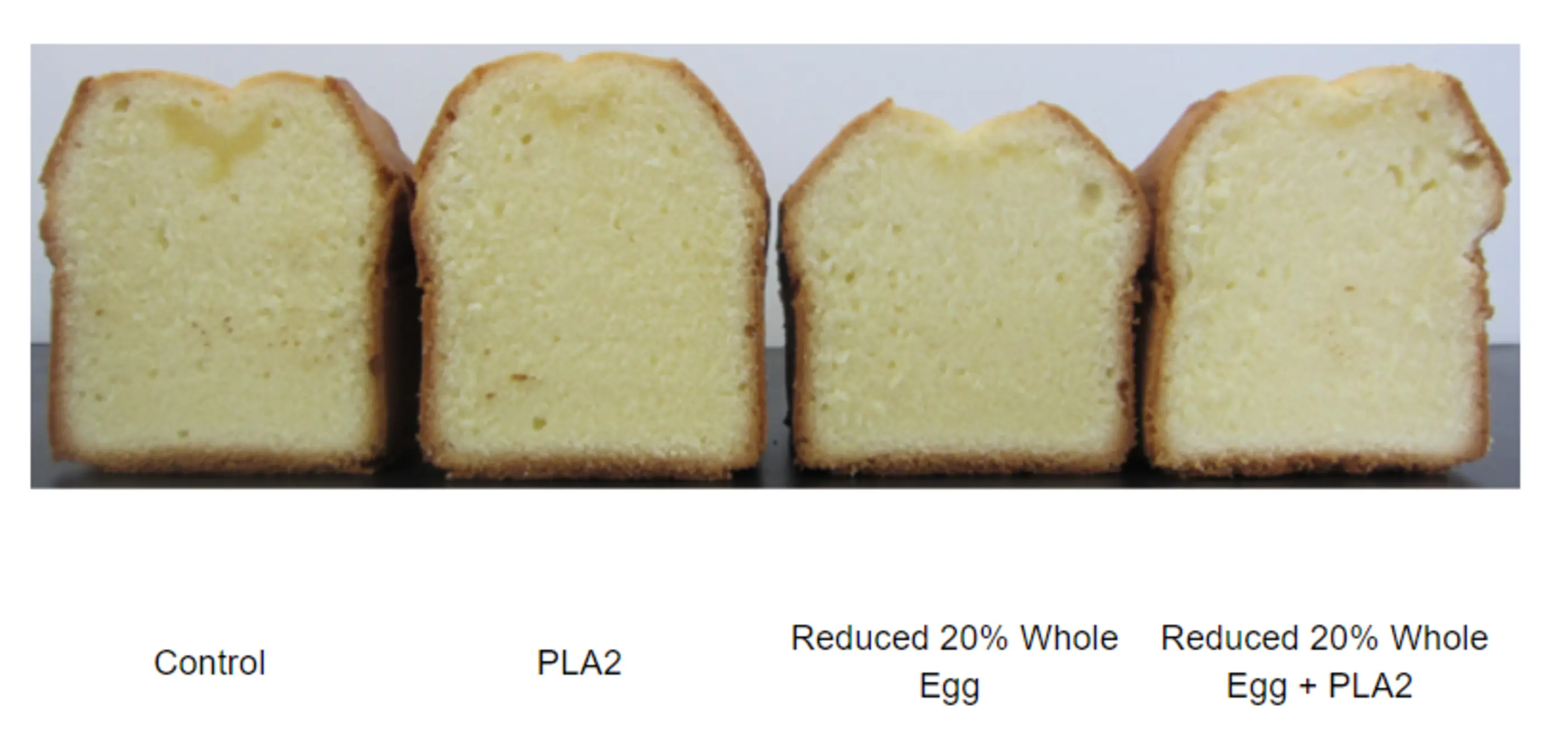

Recognizing the industry's demand for egg-reduction alternatives, we undertook a second baking experiment to investigate the impact of NAGASE PLA2 on egg replacement. Two batches of cake batter were prepared – one batch (control) had no PLA2 added, and the other batch (experimental) had a predetermined amount of PLA2 and 20% reduced egg content. In this experiment, the focus shifted to evaluating the impact of reduced egg content.

As anticipated, the reduction in egg content, resulted in noticeable structural repercussions. The reduced-egg cake exhibited undesirable symptoms post-baking, including:

Increased shrinkage: Compared to the full-egg version, the reduced-egg butter cake exhibited reduced leavening, compromising the final product's visual appeal, and likely impacting its textural qualities.

Compromised crumb structure: The reduced-egg displayed a less uniform and aerated crumb compared to its full-egg counterpart. This suggests weakened structure and stability and reduced emulsification.

In contrast, the cake batter supplemented with NAGASE PLA2 demonstrated remarkable resilience in the face of egg reduction. Even with a 20% decrease in whole egg content, the PLA2-enriched cake:

Maintained consistent volume: Unlike the significant shrinkage observed in the control, the PLA2 cake retained its original dimensions remarkably well showcasing the enzyme's effectiveness in preserving product integrity.

Preserved crumb structure: The PLA2 cake exhibited a visually similar crumb structure to the full-egg version.

These comparative results highlight the powerful egg-reduction potential of NAGASE PLA2. PLA2 can be used in butter cake preparation to partially compensate for the reduction of eggs. While PLA2 itself doesn't replace all functions of eggs, it can contribute to certain aspects that are essential for the quality of butter cakes:

Emulsification: PLA2 plays a role in breaking down phospholipids present in ingredients like flour and egg yolk. This breakdown results in the generation of lysophospholipids which can act as emulsifiers, helping to disperse fat evenly throughout the batter. Emulsification is crucial for creating a smooth and homogenous batter, contributing to a more uniform texture in the final cake.

Moisture Retention: Eggs contribute moisture to the cake, and while PLA2 doesn't directly provide moisture, the improved emulsification can help in better moisture retention and moister crumb. Structure and Texture: While PLA2 doesn't provide proteins like eggs do, the improved emulsification and fat distribution can help in creating a more stable batter. This stability can contribute to a better structure and texture in the final cake.

Reduced Dough Stickiness with PLA2

To objectively assess PLA2's impact on dough handling, a controlled mixing experiment was conducted. Two identical batches of bread dough were prepared, . However, one batch was enriched with a pre-determined dosage of NAGASE PLA2, while the other served as a control without the enzyme. Both batches underwent identical mixing protocols utilizing a standardized mixer under controlled environmental conditions.

During the mixing process, dough behavior was meticulously monitored, focusing on stickiness and handling characteristics. Strikingly, significant differences emerged between the control and PLA2-enriched doughs:

Control Dough: The control dough exhibited pronounced stickiness, adhering tenaciously to the mixer walls and paddle. Additionally, excessive stickiness can pose challenges during subsequent dough handling stages, causing production delays and potential equipment damage.

PLA2-Enriched Dough: In stark contrast, the dough supplemented with NAGASE PLA2 demonstrated a remarkable reduction in stickiness. The dough moved smoothly within the mixer, exhibiting minimal adhesion to the walls and paddle. This enhanced workability translated to smoother mixing, potentially requiring less water adjustment, and facilitating efficient processing. Moreover, reduced stickiness simplifies subsequent dough handling stages, minimizing production inefficiencies and equipment cleaning needs.

These observable differences can be attributed to PLA2's interaction with egg yolk lecithin. PLA2 interacts with egg yolk lecithin in the batter by catalyzing the hydrolysis of lecithin molecules, breaking down fatty acid chains, and reducing lipid content. This action reduces stickiness and enhances smoothness, moderating the emulsification properties of the batter and improving its rheological characteristics. Consequently, the batter flows more easily, facilitating better mixing and processing efficiency during sponge cake preparation. The experiment provides tangible evidence for PLA2's effectiveness in mitigating dough stickiness, a major pain point for bakers of all scales.

The challenges of dough handling, limited shelf life, and egg dependence no longer need to constrain your baking ambitions. NAGASE PLA2 offers innovative solutions, scientifically proven to enhance your processes, elevate product quality, and unlock new possibilities in baking. Embrace volume stability, minimize shrinkage, and maintain a soft crumb with PLA2. Experience smoother processing, reduced stickiness, and improved efficiency. Contact us today to discuss how these revolutionary ingredients can help you achieve baking excellence and propel your business forward.

Related Resources

We’re Here to Help

Complete the following fields with your information, as well as a short, detailed description of your request and a NAGASE Specialist will be in touch with you shortly.