The Next Generation of Coffee Packaging—TiMELESS® Valveless Technology

TiMELESS® is a patented packaging innovation that eliminates plastic valves, reduces costs, and keeps coffee beans in good condition. Designed to replace traditional one-way valves used in coffee bags, TiMELESS® enables brands to simplify production while making a measurable impact on sustainability.

Challenges in Coffee Packaging Today

Conventional degassing valves add cost at every step—from material procurement to installation. As prices rise and production margins tighten, cutting this extra component offers brands a smart way to lower expenses.

When gas isn’t released efficiently, bags can expand or tear during transport or on retail shelves. Beyond logistics issues, consumers often see bloated bags as a sign of poor quality, which can harm a brand’s image.

Most coffee bags combine multiple layers of plastic and foil, making them impossible to recycle. The addition of single-use plastic valves only adds to the problem. As sustainability expectations grow, brands are under pressure to reduce packaging waste and move toward circular, recyclable materials.

What is TiMELESS® ?

TiMELESS® redefines coffee packaging with built-in gas-release technology that eliminates the need for plastic valves. This innovative approach maintains coffee freshness, streamline production, and helps cut costs while reducing their environmental footprint.

The result:

- A more cost-efficient, eco-friendly, and streamlined production process.

- Coffee that maintains freshness and aroma from roastery to cup.

- A packaging solution that supports the global shift toward sustainable materials

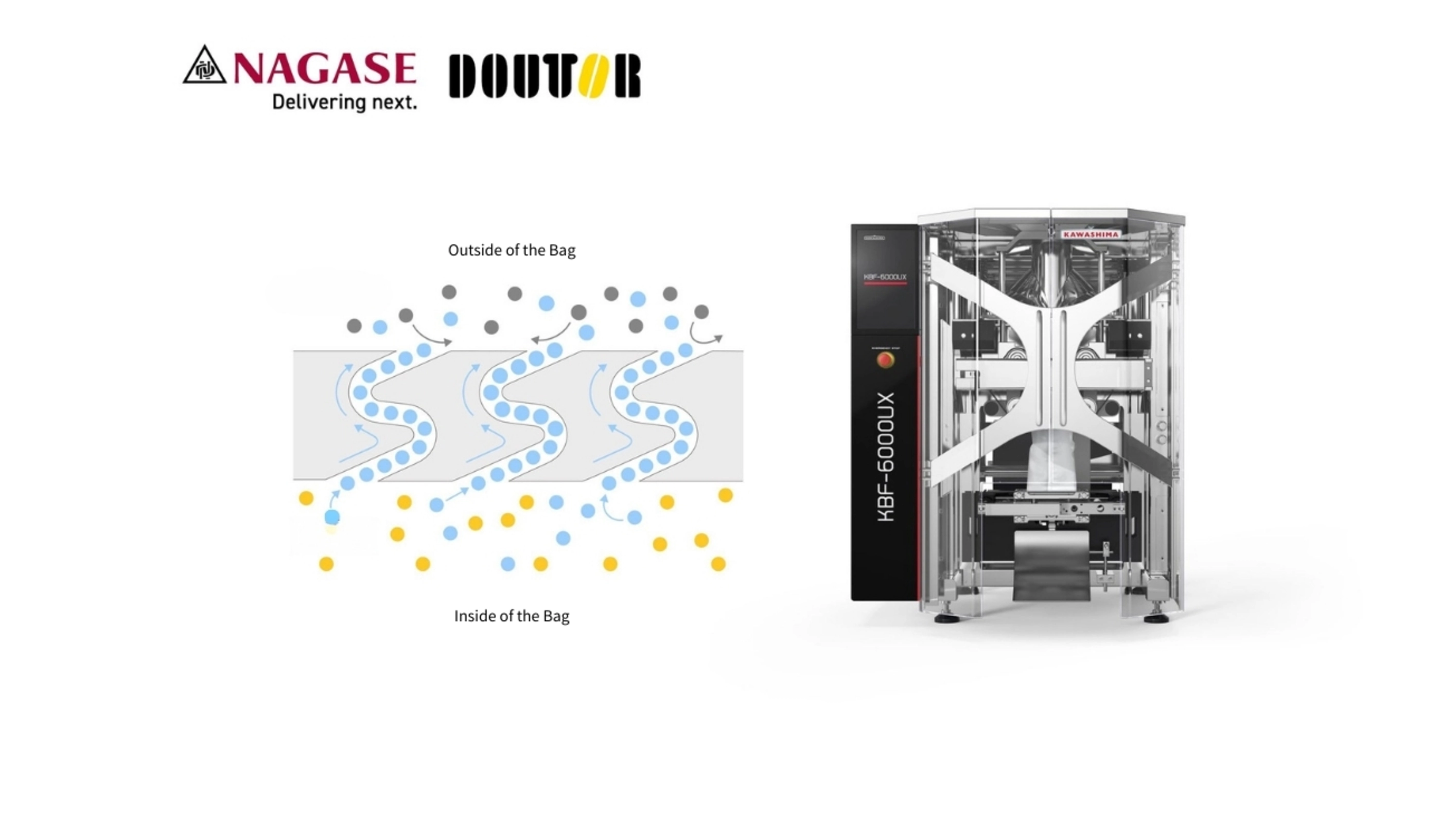

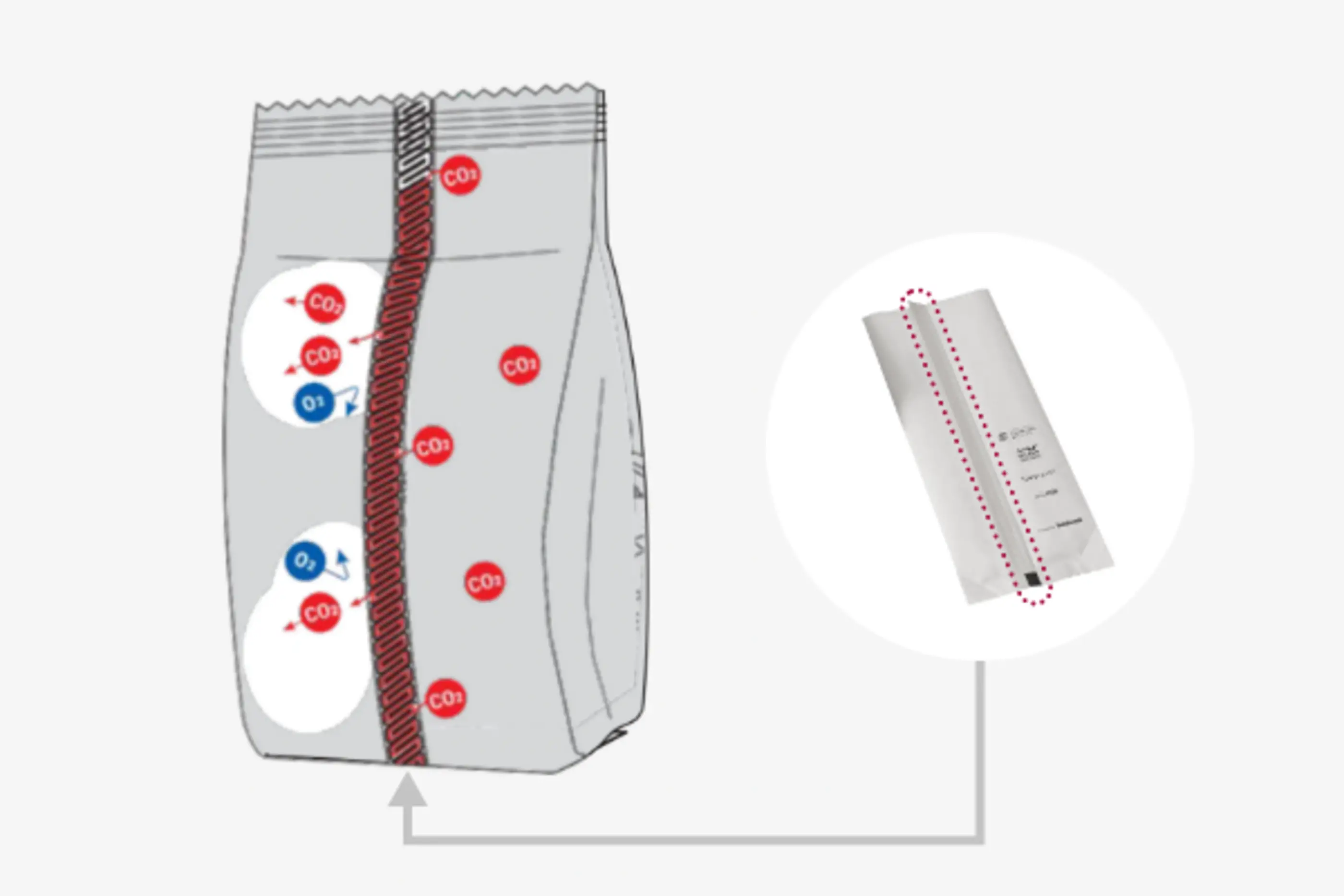

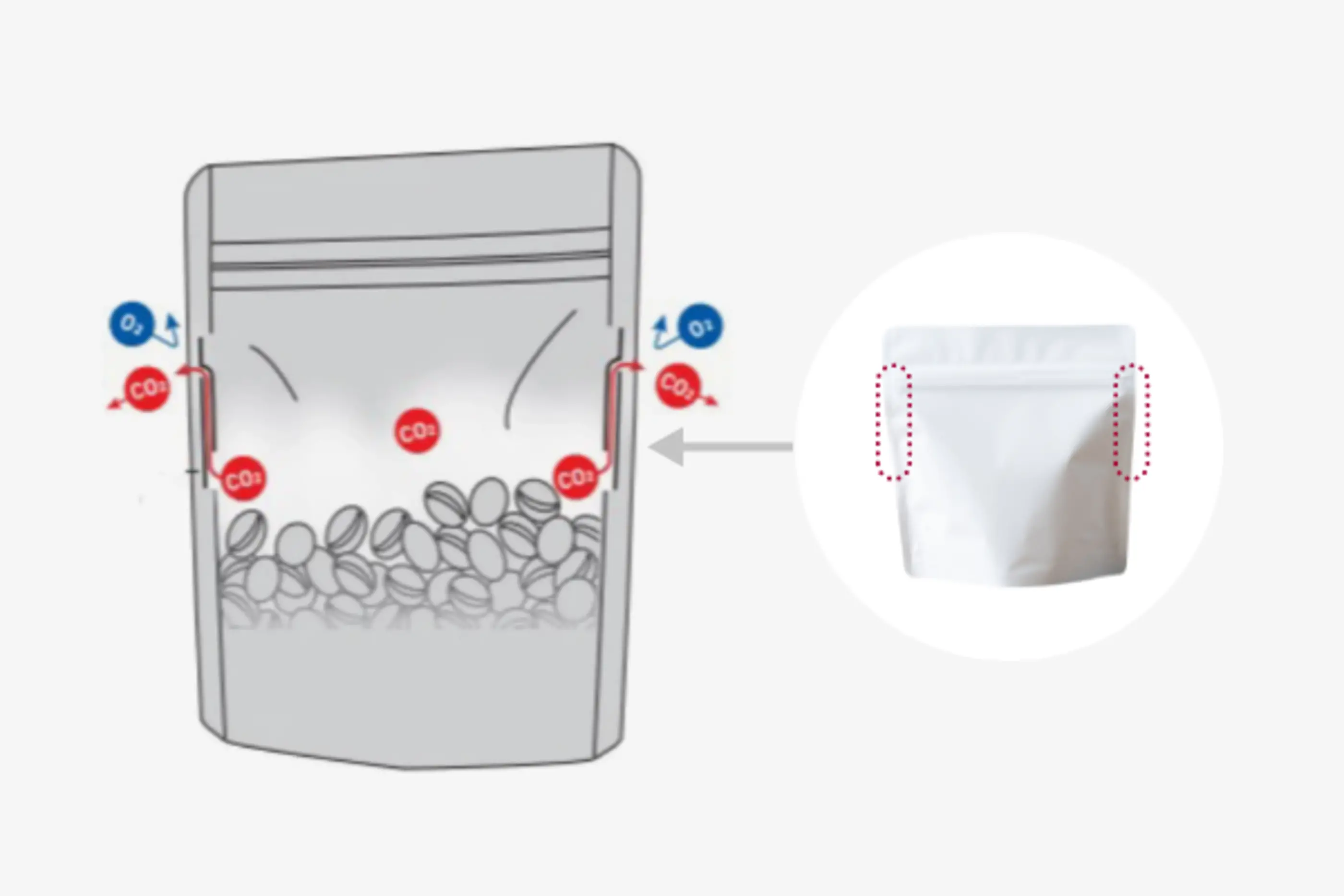

TiMELESS®'s unique microscopic flow channels expel CO2 gas generated from coffee beans while at the same time effectively preventing the intrusion of oxygen from the atmosphere.

How It Works

Valve-Free Degassing Technology

Using micro-sealing technology, TiMELESS® forms ultra-fine flow channels within the seal of the packaging film. These channels allow CO2 released by freshly roasted beans to escape, while blocking oxygen from entering. This simple yet powerful structure maintains freshness—without any plastic valve.

Gusset | Flat Bag

Stand-up Pouch

Key Advantages of TiMELESS®

Flow channels are ultrasonically formed directly into film or paper packaging—no valve parts, no manual installation. Coffee can be packed immediately after roasting, eliminating the need for aging or degassing time. That means fewer steps, fewer materials, and lower labor costs.

Request Free Sample*By removing the dependency on specialty valve components, TiMELESS® helps brands mitigate supply-chain risks and material shortages—while enabling a seamless transition to sustainable packaging

Request Free Sample*US alone uses approximately 1.8 billion plastic degassing valves per year (as of 2025). TiMELESS® eliminates these entirely. Because it can be produced from a single recyclable material, it supports the shift toward mono-material packaging, promotes resource recovery, and reduces overall environmental impact.

Request Free Sample** Requests are subject to sales team review and approval. Samples are available in limited quantities and provided at Nagase's discretion to qualifying customers.

TiMELESS® Packaging Solutions to Fit Your Business

Whether you’re a small roaster or a large-scale producer, TiMELESS® offers flexible adoption paths:

Integration with Packaging Lines

(Available globally)

For mass production, TiMELESS® can be built into new or existing vertical form-fill-seal (VFFS) equipment. Our engineers provide full technical support for implementation and optimization.

Custom Packaging

(Currently only available in Japan)

For premium brands, TiMELESS® can be integrated into your own custom packaging design (shape, size, print). Orders start from approximately 20,000 bags (200 g size).

Standard Bags

(Currently only available in Japan)

Perfect for small batches or pilot runs—order stand-up pouches or gusset bags in quantities as low as 100 units.

*Requests are subject to sales team review and approval. Samples are available in limited quantities and provided at Nagase's discretion to qualifying customers.

FAQs

Most heat-sealable films and papers can be used. If you have specific substrates in mind, our team can test and verify compatibility.

Some existing VFFS machines can be modified, though we generally recommend using equipment designed for TiMELESS® for best results.

TiMELESS® removes the need for plastic valves, reducing plastic consumption and improving recyclability—key steps toward sustainable packaging.

Beyond Coffee

TiMELESS® micro-sealing technology is also suitable for:

Fresh produce packaging

to control gas exchange and moisture retention

Frozen foods packaging

to improve freshness and eliminate unnecessary materials

The Story Behind TiMELESS®

The Nagase Group developed TiMELESS® with a mission to reduce environmental impact and preserve resources for the future. By replacing plastic valves with an integrated degassing channel, TiMELESS® lowers costs and supports a circular economy—benefiting both businesses and the planet.

Featured Resources

We’re Here to Help

Complete the following fields with your information, as well as a short, detailed description of your request and a NAGASE Specialist will be in touch with you shortly.