Without a revolutionary lightweight and stable substrate, aerospace missions risk higher costs, degraded performance, and reduced satellite lifespan.

Xenomax®︎: Transforming Aerospace Solar Power with Groundbreaking Lightweight Innovation

March 28, 2025

From Electronic Paper to Space Power Pioneer

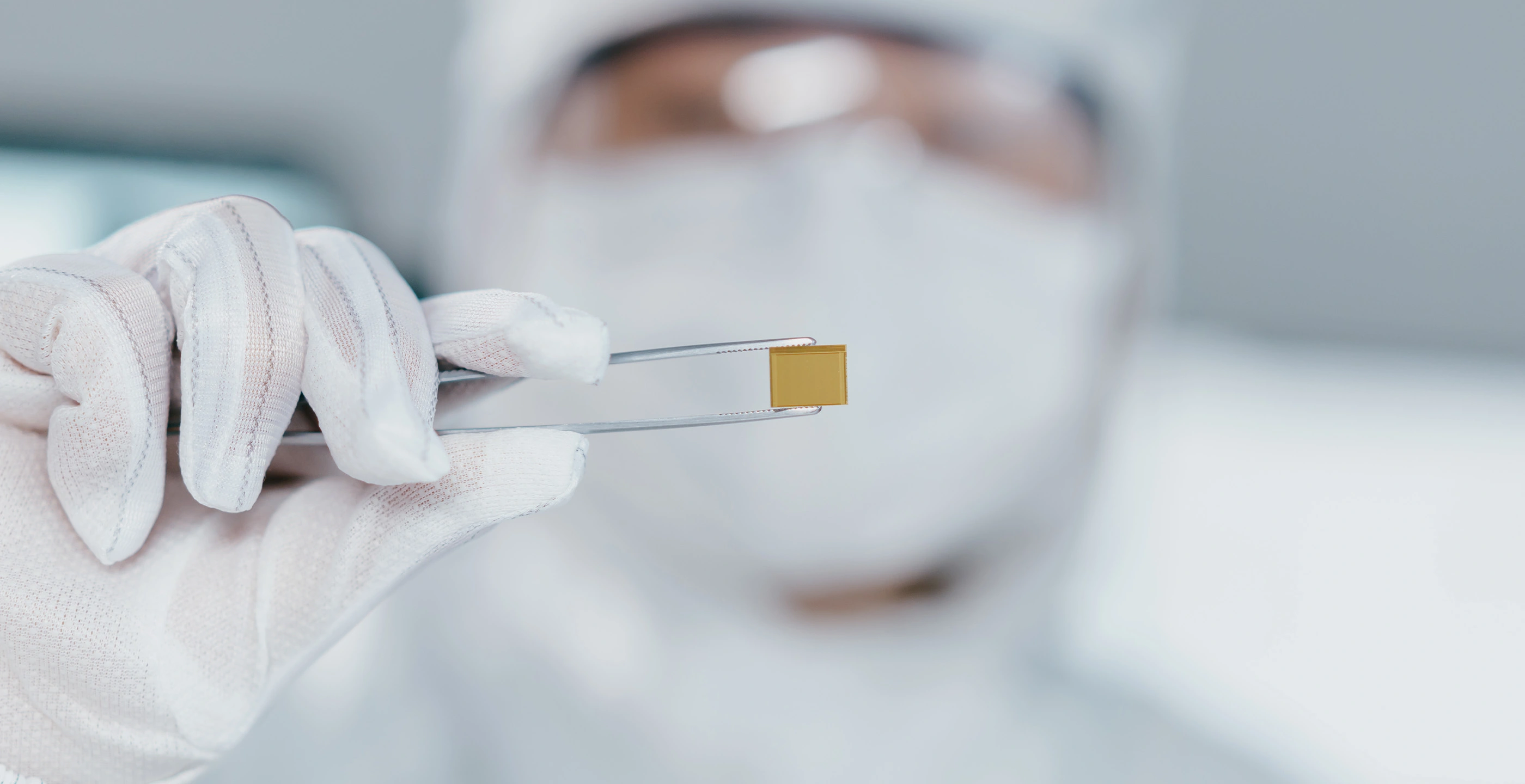

Established through a strategic partnership between TOYOBO CO., LTD. and Nagase & Co., Ltd., Xenomax Japan Co., Ltd. has operated an exclusive production facility at Toyobo Tsuruga Factory (Fukui Prefecture, Japan) since 2018. Initially designed for electronic paper displays, the revolutionary Xenomax® polyimide film quickly found its true calling transforming solar technology for aerospace applications.

Aerospace Engineers Face Solar Power Dilemma

Satellite technology is advancing rapidly, yet Chief Scientists and System Engineers confront increasing pressure to enhance photovoltaic efficiency while cutting payload weight and ensuring long lasting performance. Traditional solar cell substrates like glass and polymer films struggle under extreme conditions, causing:

- Launch Weight Woes: Heavier substrates dramatically inflate launch costs.

- Thermal Nightmare: Constant temperature extremes in space cause traditional materials to warp, degrade, and fail.

- Manufacturing Challenges: Standard polymer films deform at high temperatures, limiting solar cell quality and efficiency.

- Deployment Difficulties: Satellite solar arrays must compactly store and deploy smoothly, posing complex engineering challenges.

Lightweight, Robust, and Reliable: The Xenomax® Solution

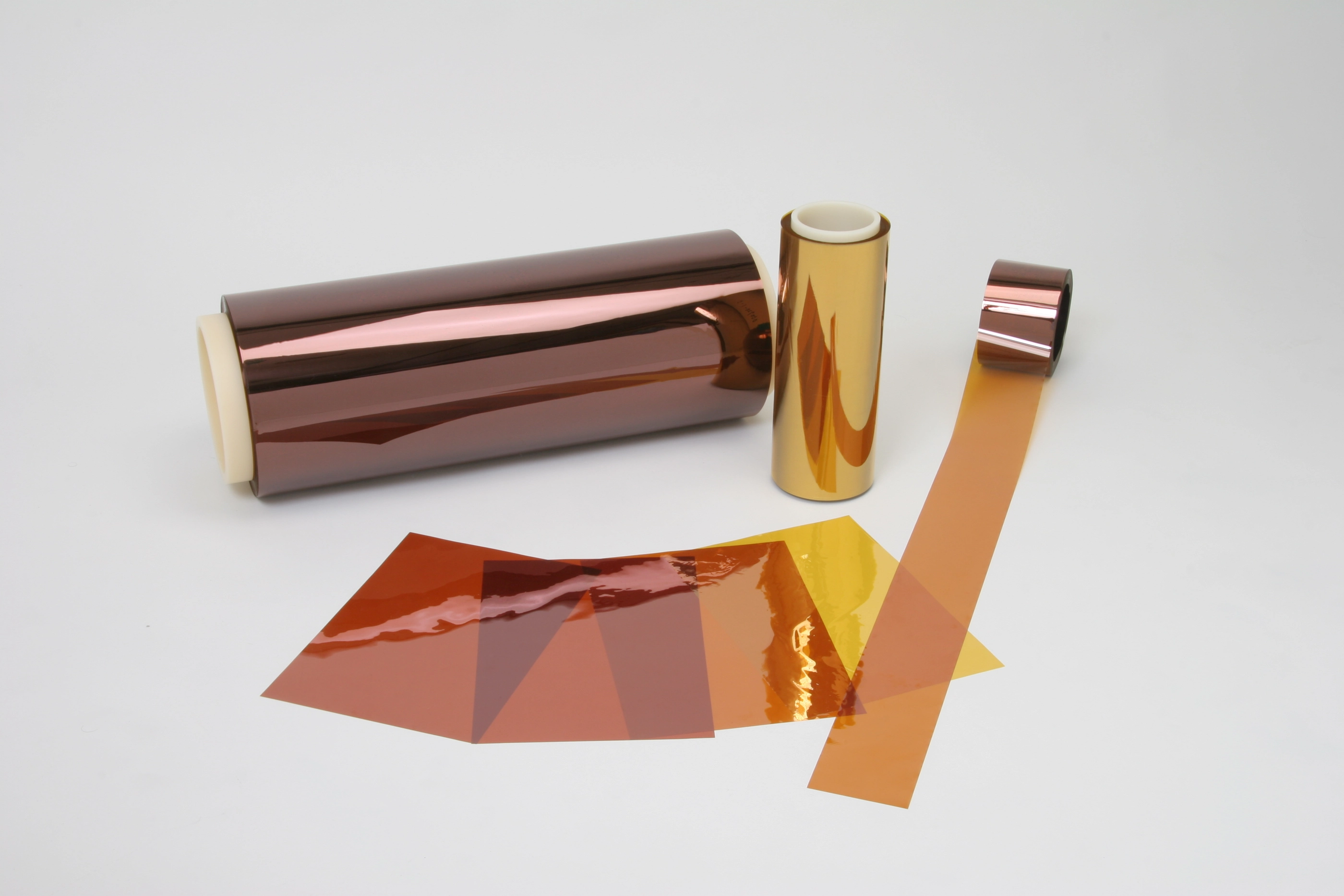

Xenomax® polyimide film boldly tackles these aerospace challenges, delivering unprecedented performance:

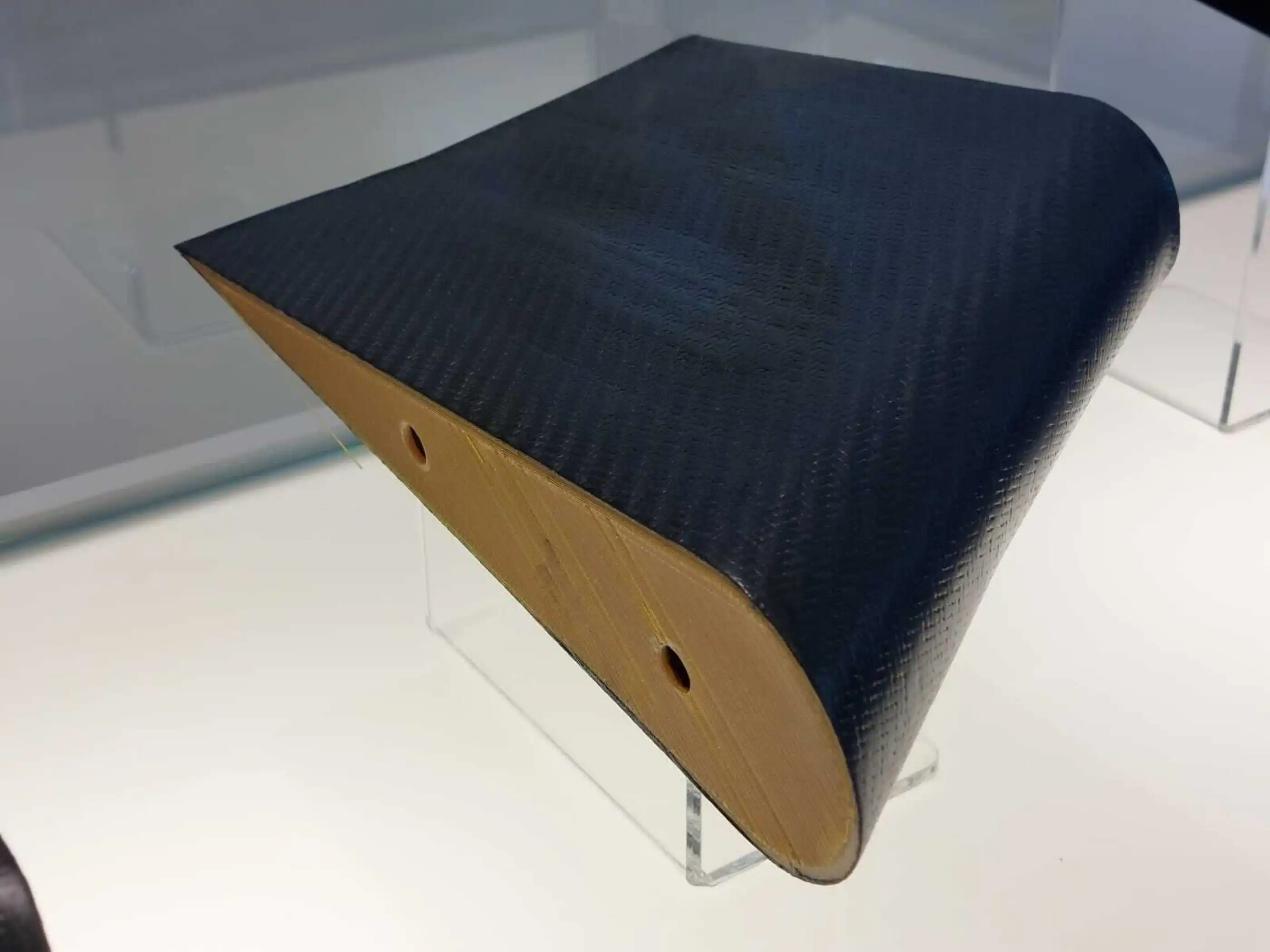

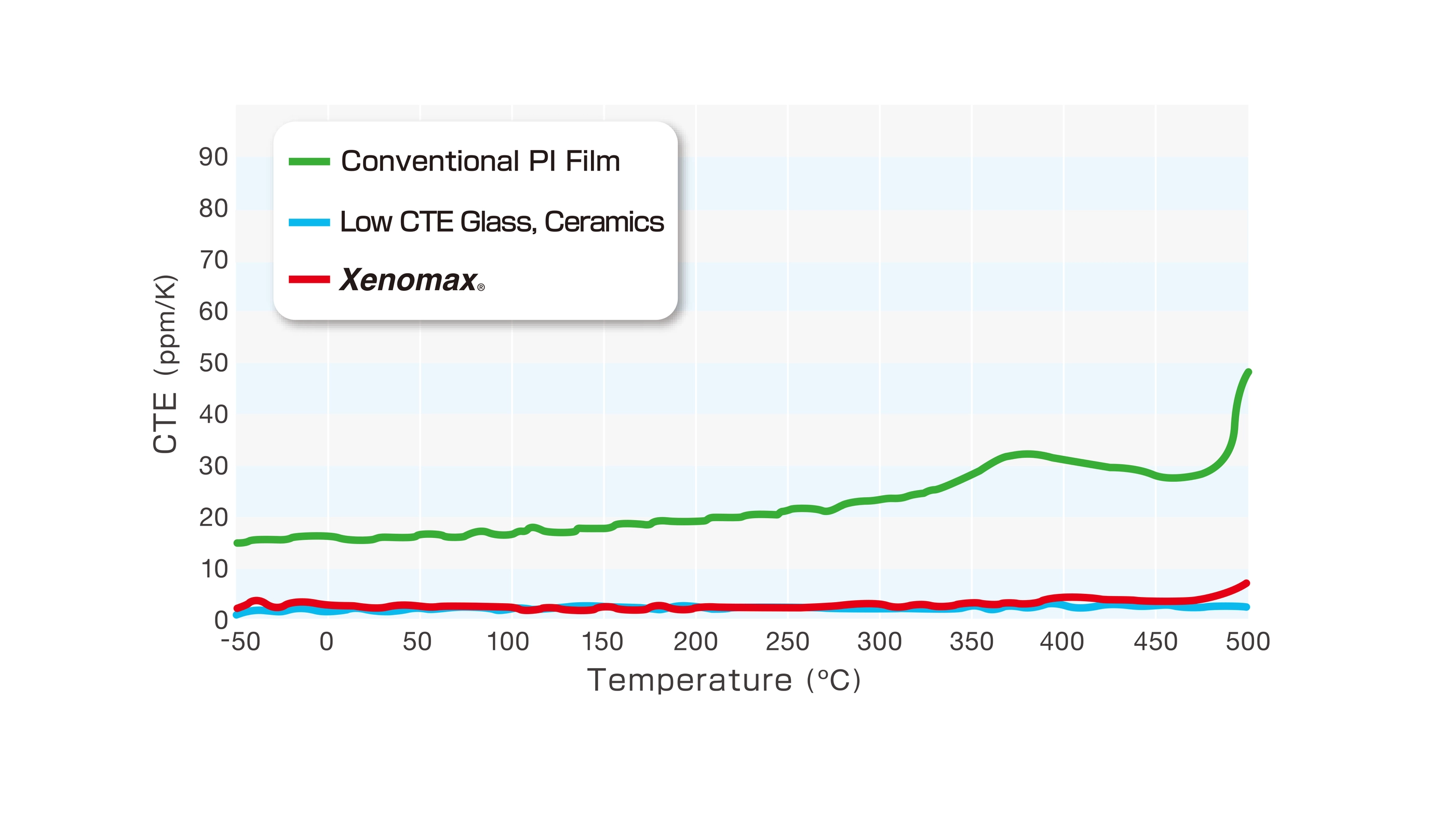

- Excellent Dimensional Stability: With an exceptionally low coefficient of thermal expansion (CTE), comparable to glass, Xenomax® provides unparalleled dimensional stability even during extreme thermal cycling ( 170°C to 150°C).

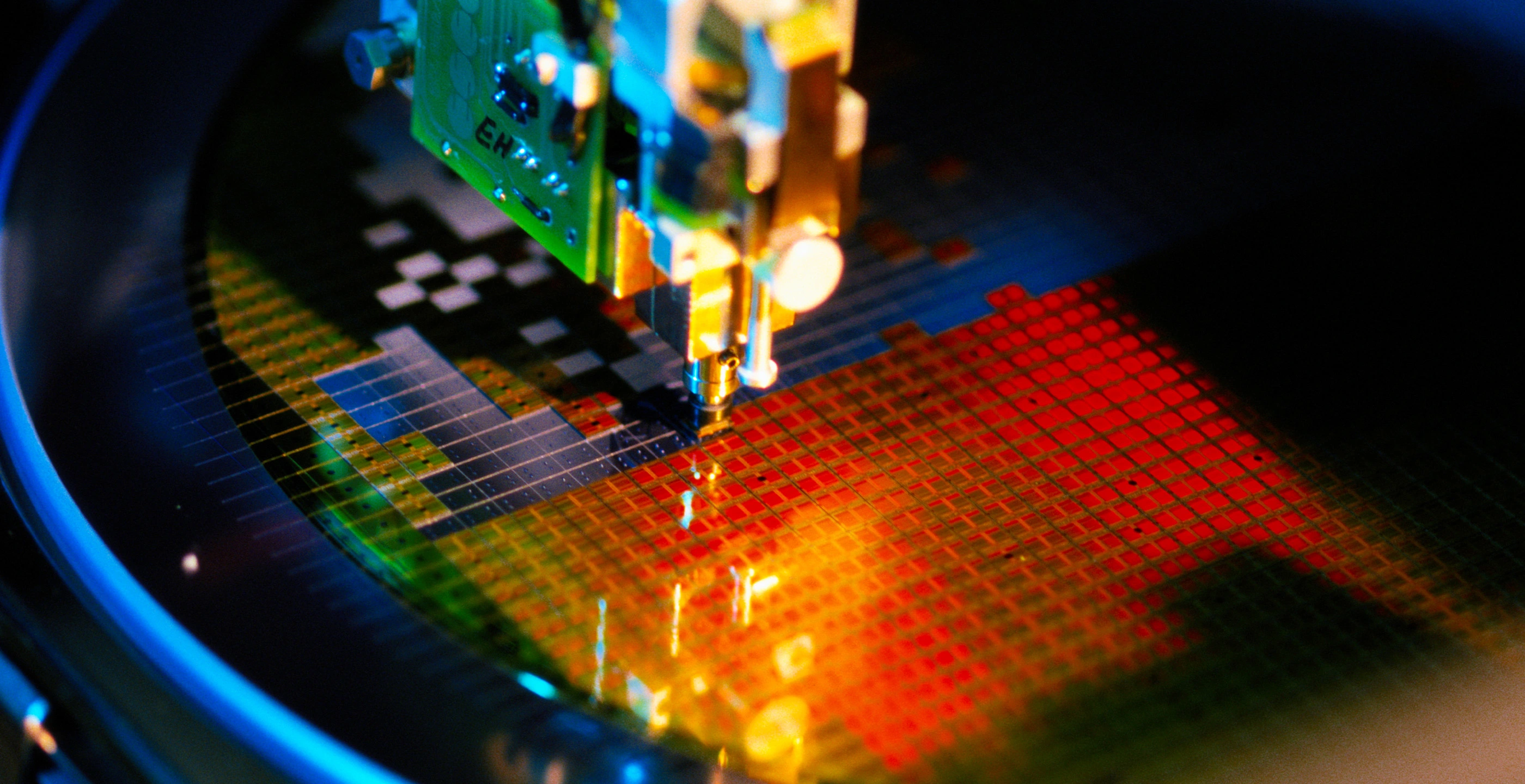

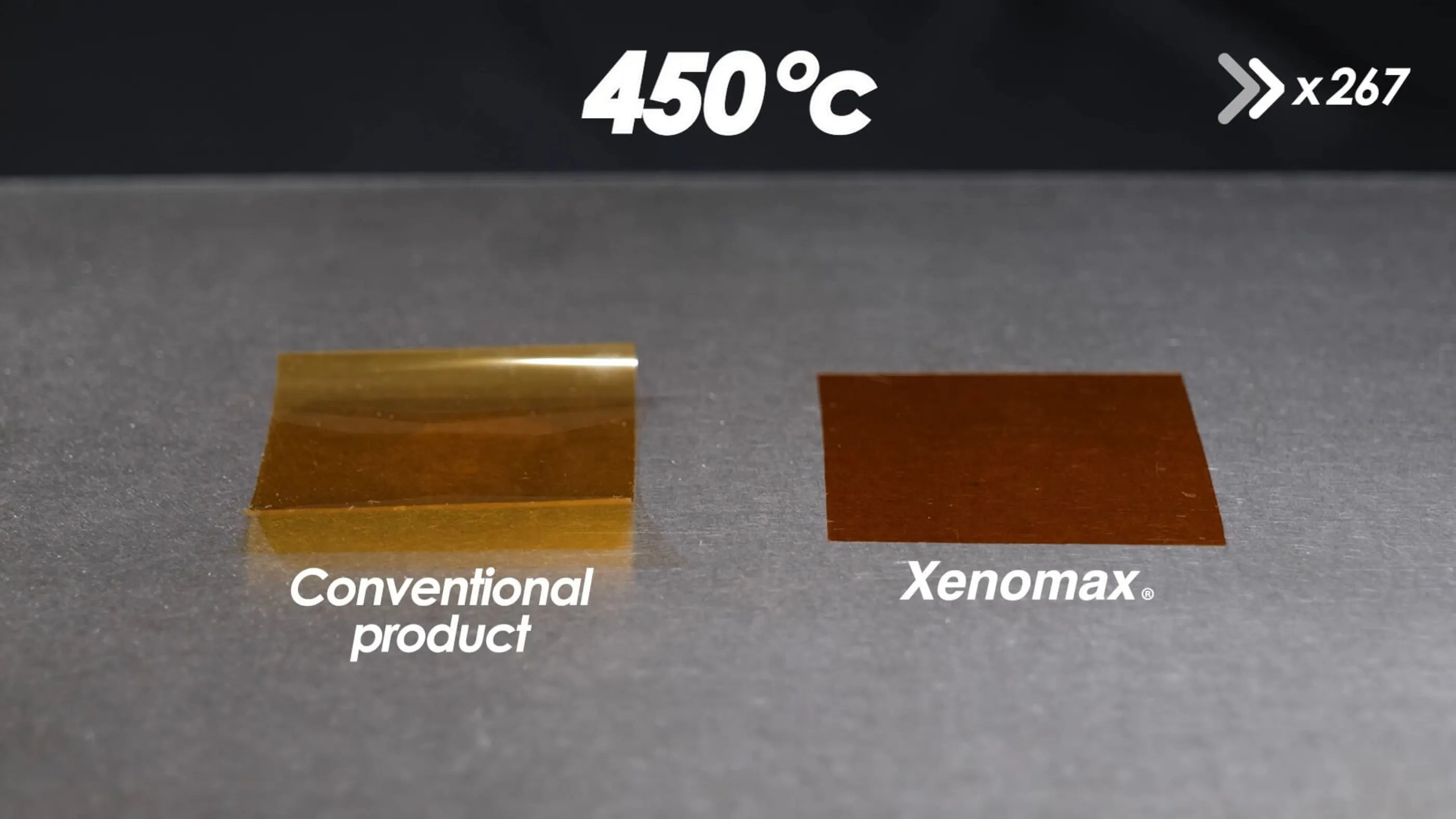

- Superior Heat Resistance: Exhibits no warpage at temperatures up to 450°C, allowing higher temperature processes in CIGS solar cell manufacturing, significantly boosting conversion efficiency.

- Excellent Surface Flatness: Achieves surface flatness comparable to glass substrates (Ra≒0.5nm), ensuring optimal performance and reliability of photovoltaic cells.

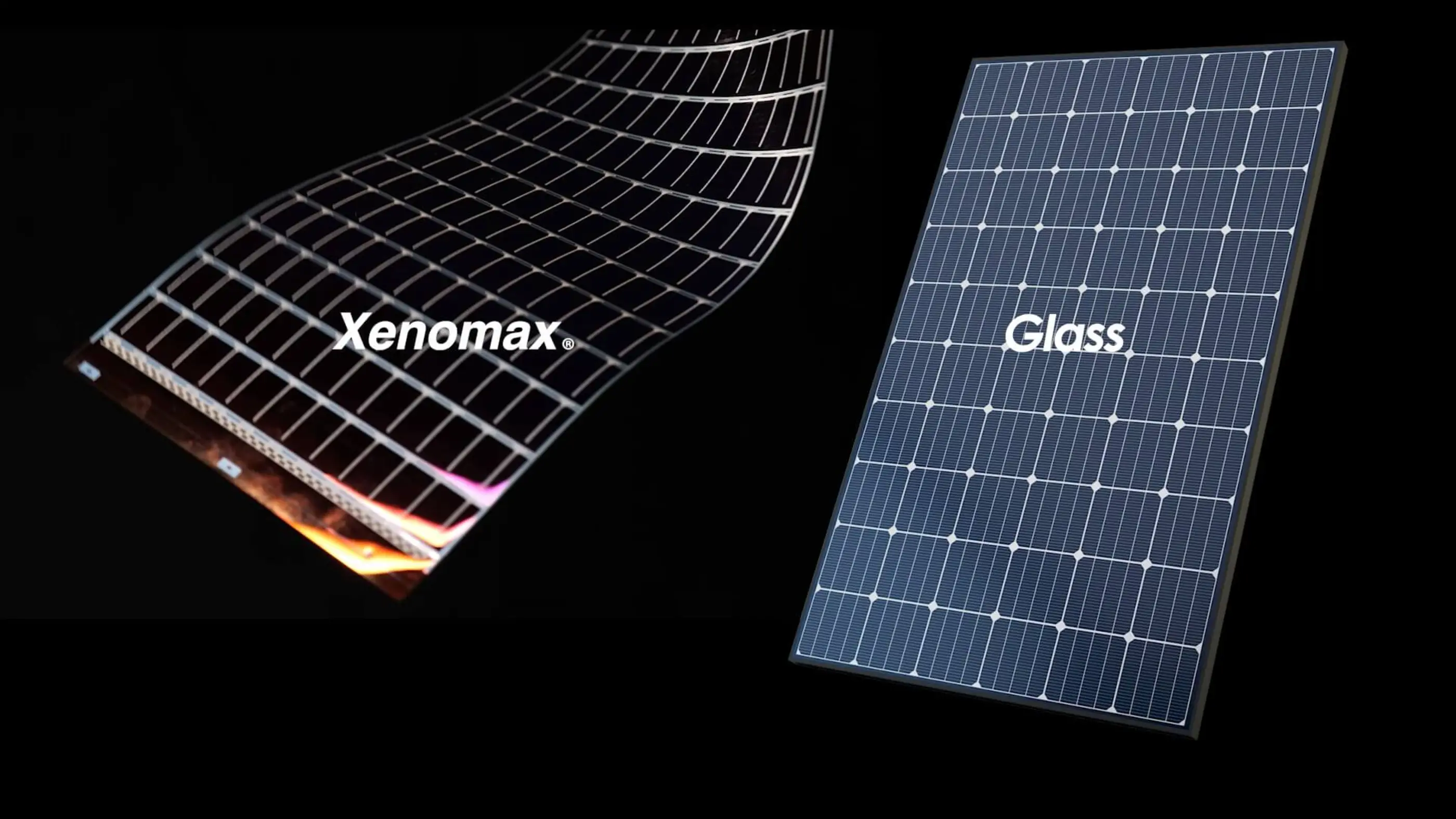

- Ultra-Lightweight & Flexible: Dramatically reduces payload weight, simplifies logistics, and enables reliable deployment in orbit. More than 99% lighter than conventional glass substrates (0.8mm thickness).

- Stable Supply: Reliable availability in both small and large quantities to meet varying demands of aerospace applications.

Promising Results from Rigorous Testing

While currently in advanced testing stages, Xenomax®︎ is demonstrating significant promise in aerospace applications:

- Enables lighter, more compact solar arrays for seamless deployment and maximum efficiency in space missions.

- Exhibits exceptional dimensional stability through extensive and rigorous thermal cycling tests, simulating space conditions.

- Proven durability and heat resistance in laboratory conditions, positioning Xenomax®︎ as a strong candidate for future satellites and high altitude platform stations.

Results That Speak Volumes

Xenomax® delivers transformative benefits to aerospace solar solutions:

Achieves a 99% reduction in weight compared to glass substrates.

Elevated energy efficiency via improved thermal stability and high temperature processing capabilities.

Substantially lowers launch costs thanks to dramatic payload weight reductions.

Ongoing testing shows Xenomax® improves solar durability with its dimensional stability and thermal resistance—ideal for aerospace photovoltaic use.

The Future of Aerospace Solar Arrays

Xenomax® continues to lead innovation in aerospace, expanding its footprint in next generation satellite and photovoltaic technologies. Its lightweight, thermally stable solutions offer aerospace engineers an essential advantage in achieving mission success.

Key Takeaways for Aerospace Innovation

Lightweight materials dramatically improve aerospace cost efficiency.

Dimensional stability guarantees reliable, long term solar cell performance.

Elevated temperature processing significantly enhances solar array efficiency and quality.

Featured Resources

We’re Here to Help

Complete the following fields with your information, as well as a short, detailed description of your request and a NAGASE Specialist will be in touch with you shortly.