We installed it easily during short downtime thanks to the magnetic sheet design. Temperatures around key components fell, boosting efficiency, and low install cost allowed for a quick ROI.

SPACECOOL™ Radiative Cooling Material (PDRC)

Reduce thermal risk without increasing energy use. SPACECOOL™ is an advanced passive daytime radiative cooling (PDRC) material engineered to cool equipment below ambient temperature, even in direct sunlight. Its unique optical structure combines ultra-high solar reflectance and strong mid-infrared emissivity to passively emit heat through the atmospheric window—achieving true radiative cooling with no electricity, fans or moving parts.

Common Thermal Pain Points in Outdoor Equipment

Equipment Failure

Heat accelerates degradation of internal electronics, leading to instability, faults, or premature failure.

Measurement Error

Temperature fluctuations cause drift in sensors and instruments, compromising measurement accuracy.

CO₂ Emissions

Active cooling systems rely on electricity, contributing to higher energy consumption and increased CO2 output.

What Is SPACECOOL?

SPACECOOL is a next-generation PDRC (Passive Daytime Radiative Cooling) material that lowers temperatures 2–6°C below the surrounding air without any energy consumption.. It achieves advanced PDRC performance by combining:

- Ultra-high solar reflectance to minimize heat absorption (0.3–2.5 μm), and

- Strong thermal emissivity in the 8–13 µm atmospheric window, enabling efficient radiative heat loss to the sky.

This passive, maintenance-free cooling technology reduces heat stress and significantly improves the reliability of outdoor electronics and systems—without electricity,

Refrigerants or mechanical cooling devices.

Ultra-high solar reflectance (~95%) and high mid-IRstrong emissivity in the 8–13 µm atmospheric window for maximum PDRC efficiency.

Designed for real-world outdoor environments, SPACECOOL provides 10–15 years of stable radiative-cooling performance.

Magnet-sheet configuration enables tool-less installation and simplified maintenance.

SPACECOOL can reduce surface temperatures by 2–6°C below ambient under direct summer sunlight. Its radiative cooling capacity is 120–150 W/m², depending on weather conditions and internal heat load.

*Actual performance may vary based on environmental factors and equipment usage.

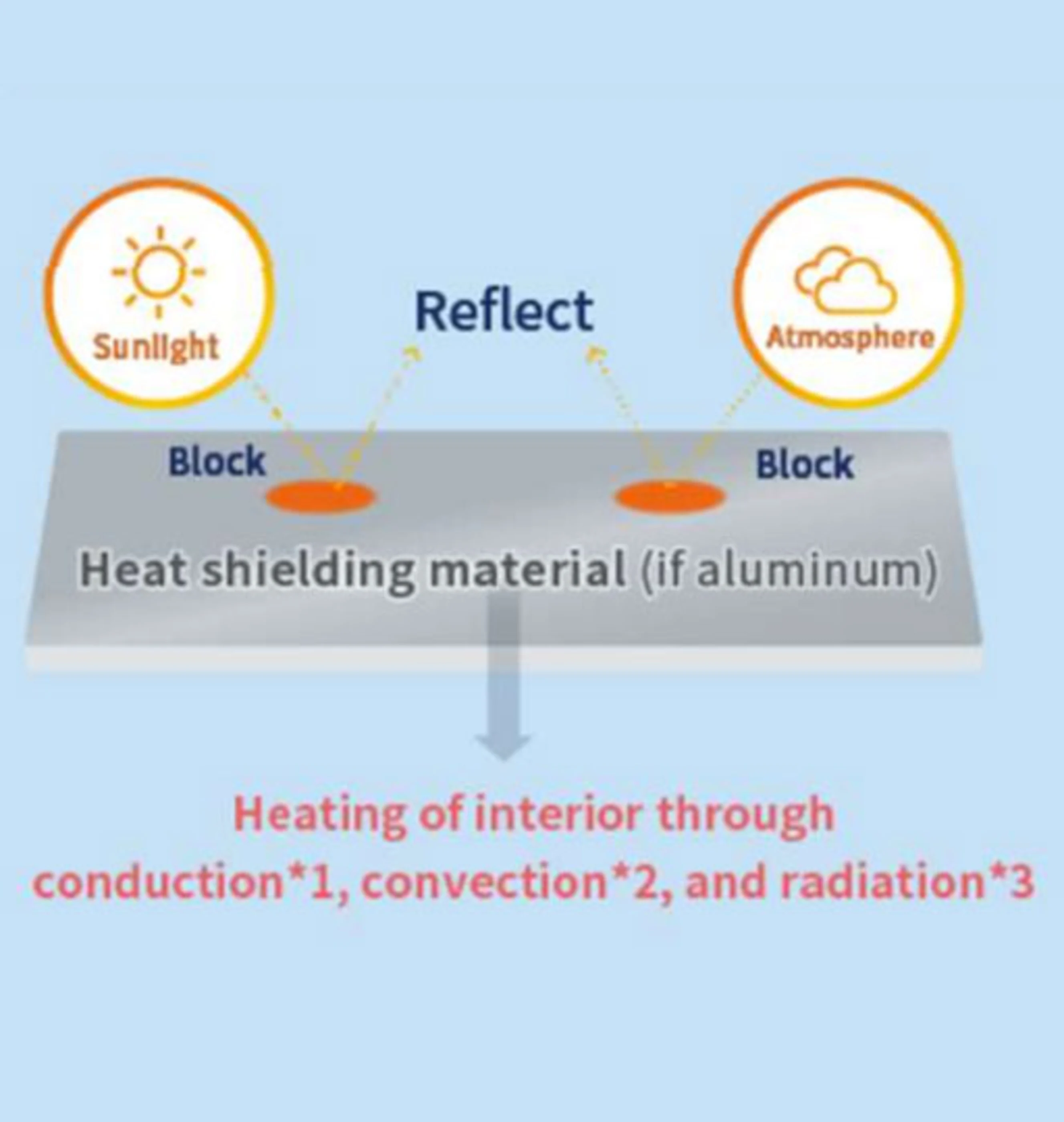

Comparison to Conventional White Paint & Reflective Coatings

Traditional White Paint & Reflective Coatings

(Conventional reflective coatings not true PDRC materials)

Reflect sunlight but do not release their own heat effectively.

High reflectance, low emissivity → heat becomes trapped.

Cooling stops at ambient air temperature; cannot achieve sub-ambient cooling.

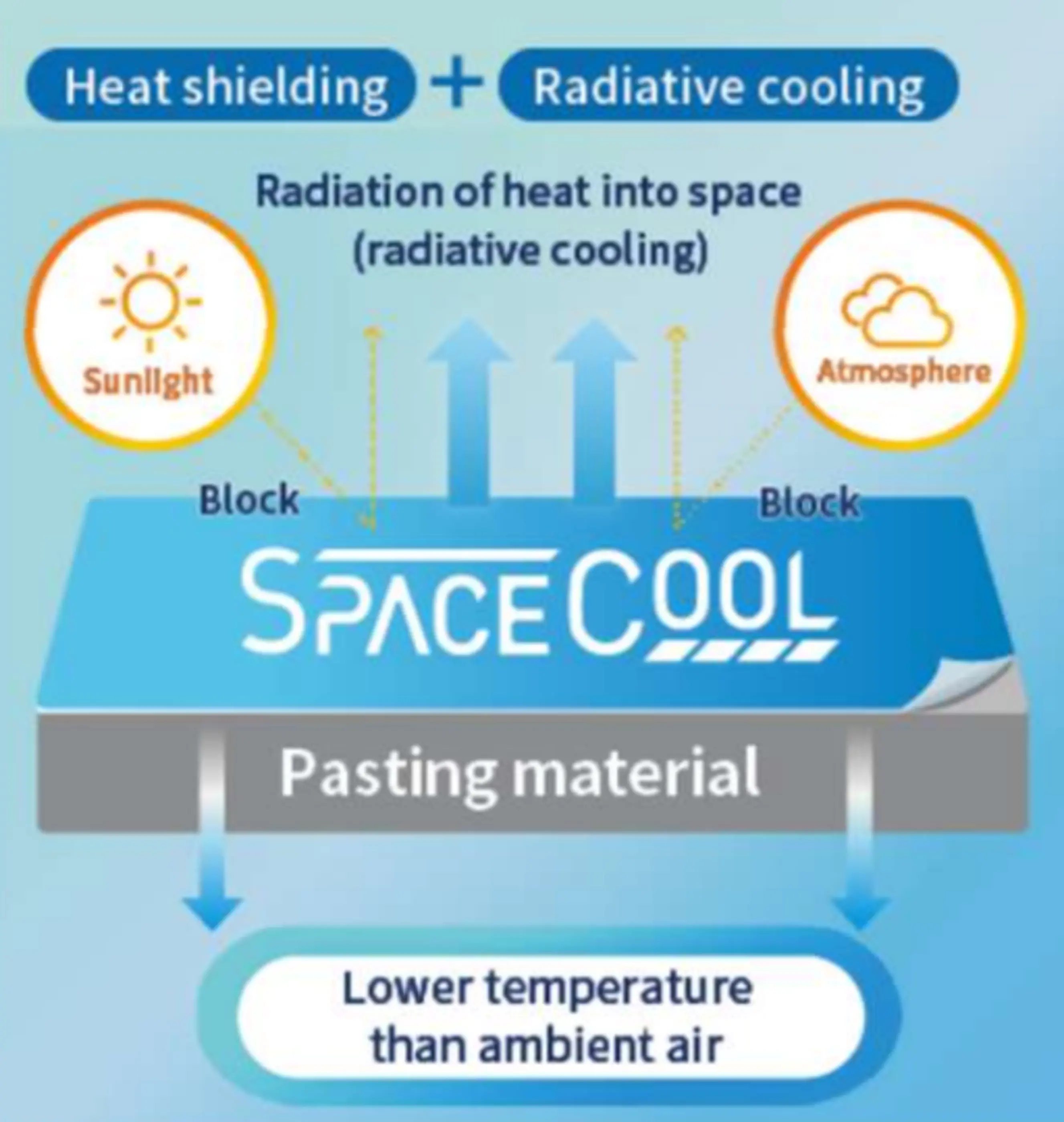

SPACECOOL Radiative Cooling

(Reflective + high-emissivity + wavelength-selective design)

SPACECOOL was engineered to do both: keep sunlight out and send heat out. Its structure reflects almost all solar radiation and emits infrared heat through a natural atmospheric window. Using wavelength-selective optics it achieves: high reflectance of solar radiation (0.3–2.5 μm) and high emissivity in the atmospheric window (8–13 μm).

Consistent sub-ambient cooling, even under sunlight, with zero energy.

| Property | White Paint / Reflective Coatings | SPACECOOL™ (PDRC Material) |

|---|---|---|

| Solar Reflection | High | Very High |

| Thermal Emission (8–13 μm) | Low | High |

| Ability to Cool Below Ambient | No | Yes (PDRC) |

| Mechanism | Heat shielding only | Heat shielding + radiative cooling (PDRC) |

Applications & Benefits

Outdoor Electrical Enclosures

HVAC Outdoor Units

SPACECOOL™ delivers passive, zero-energy cooling performance. It prevents equipment failure, performance degradation, and measurement errors caused by solar heat gain in outdoor HVAC units and electronic control systems.

Benefits

- Extended equipment lifespan

- Reduced maintenance costs

- Higher measurement accuracy

- Increased system reliability

- Reduced cooling load and operating costs

- Lower CO2 emissions

Product Lineup

| Attribute | White Film | Silver Film | High-Durability Film | Magnet Sheet |

|---|---|---|---|---|

| Part # | SCF-A25M-XNW | SCF-A25M-XNS | SCF-2BXX-XNW | SCG-040I-KXW |

| Size | 1250 mm × 25 m | 1250 mm × 25 m | 1250 mm × 25 m | 1020 mm × 10 m |

| Thickness | 110 μm | 110 μm | 230 μm | ~0.58 mm |

| Weight | 145 g/m² | 145 g/m² | 255 g/m² | ~1490 g/m² |

| Base Material | PVC | PVC | PVC | PVC + Magnetic Sheet |

| Durability | ~10 years | ~10 years | ~15 years | ~15 years |

| Combustion Rating | Non-combustible | Non-combustible | Non-combustible | — |

| Adhesion | Acrylic PSA | Acrylic PSA | Acrylic PSA | Magnetic bonding |

| Certification | MLIT Noncombustible Certification: NM-5427 / 5428 / 5429 | MLIT Noncombustible Certification: NM-5427 / 5428 / 5429 | MLIT Noncombustible Certification: NM-5897, NM-5898 | — |

| Test Method | Thickness measured in accordance with ISO 4593. Property values are generally based on test results obtained at 20°C and 65% relative humidity, unless otherwise specified. | Thickness measured in accordance with ISO 4593. Property values are generally based on test results obtained at 20°C and 65% relative humidity, unless otherwise specified. | Thickness measured in accordance with ISO 4593. Property values are generally based on test results obtained at 20°C and 65% relative humidity, unless otherwise specified. | — |

User Testimonials

(Application: Outdoor air-conditioning unit)

Its energy-free heat-shielding and radiative-cooling performance impressed us, as did the easy installation and zero operating costs. These benefits made it an ideal candidate for testing.

(Application: Communication station building)

Frequently Asked Questions (FAQ)

Pricing varies by material type.

Share a few details with us through the inquiry form, and we’ll prepare a quote tailored to your needs.

If helpful, we can also provide an estimate that includes installation costs.

Our products are available as standard full-roll units, and we also offer cut samples for evaluation.

Simply let us know your required size or application when you contact us.

While shipments are typically domestic (Japan), we can support overseas delivery depending on the requirements.

Reach out via the inquiry form, and we’ll review your needs together.

Yes, samples are available.

Most samples are provided on a paid basis, but we may be able to offer no-charge samples depending on the project.

Contact us and we’ll guide you through the best option.

Yes. Product catalogs, case studies, and installation guides are available.

Tell us which materials you need, and we’ll provide them.

Why Partner with NAGASE?

NAGASE brings together global trading expertise, specialized manufacturing capabilities, and in-house R&D—enabling us to support the successful deployment of advanced technologies like PDRC materials across industries.

Our integrated model allows us to identify customer needs early, provide technical guidance, and deliver high-value materials and solutions backed by long-term partnership and support.

We’re Here to Help

Complete the following fields with your information, as well as a short, detailed description of your request and a NAGASE Specialist will be in touch with you shortly.