We’re Here to Help

Complete the following fields with your information, as well as a short, detailed description of your request and a NAGASE Specialist will be in touch with you shortly.

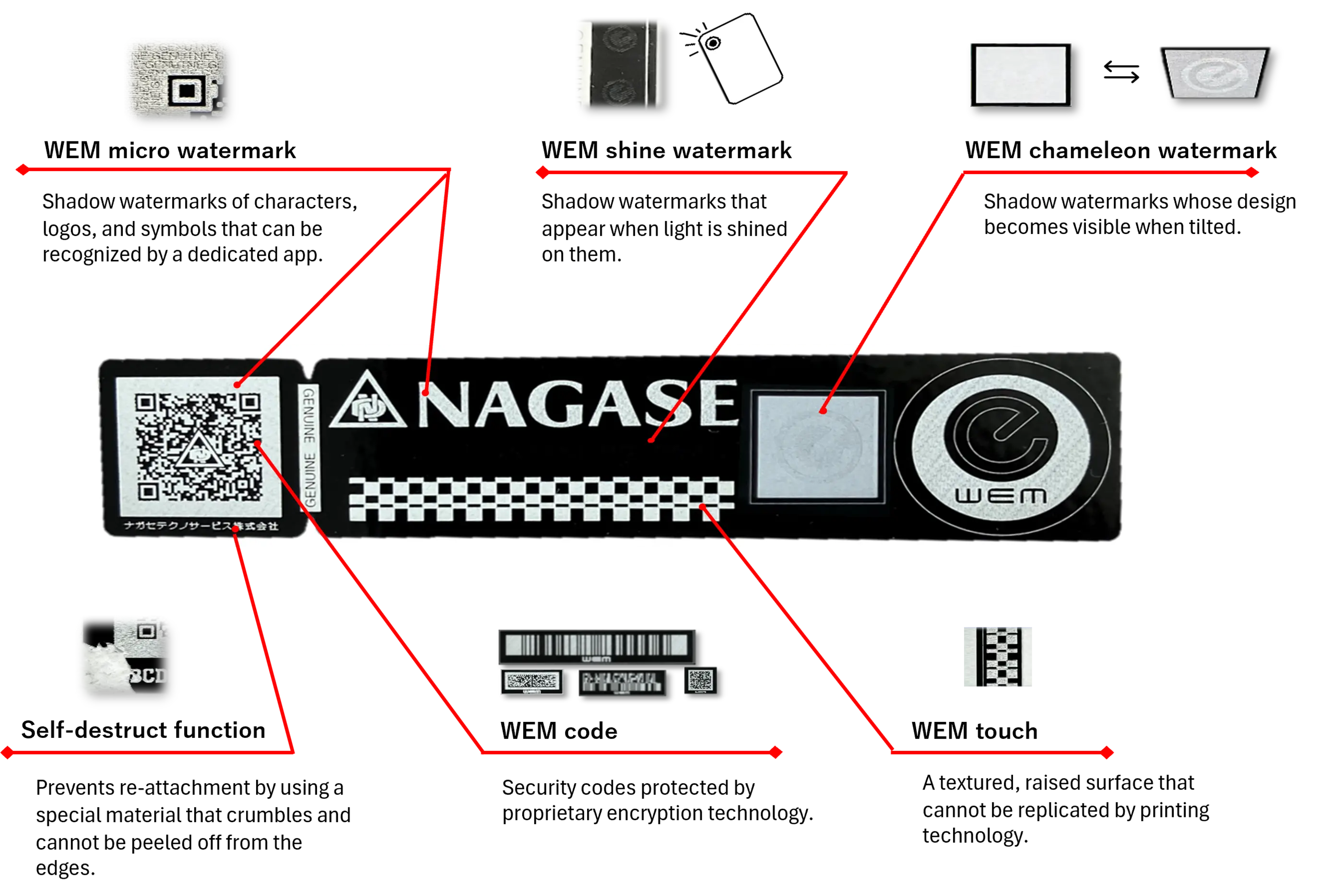

WEM® Technology is a patented, laser-based authentication system that embeds physically non-replicable micro-structures directly into materials. Unlike printed security features or digital identifiers, WEM® relies on micrometer-scale three-dimensional surface geometry that cannot be duplicated—even with advanced laser or precision manufacturing systems.

This makes WEM® suitable for applications where technical authenticity, traceability, and material integrity are critical.

Patented Watermark-Engraving Technology

・Authentication based on controlled light reflection and surface geometry

・Impossible to reproduce—even with advanced laser or precision manufacturing systems

・Customizable engraving specifications tailored to each product

Dedicated Authentication Application

・Fast visual and tactile pre-check

・High-precision verification using a dedicated app

・Compatible with smartphones, browser-based tools, and inspection terminals

Designed to Integrate with Existing Processes

・Works with tamper-evident stickers, direct engraving, and mold-transfer applications

・Flexible watermark size, geometry, and placement

・Optional integration with QR codes or serialized data

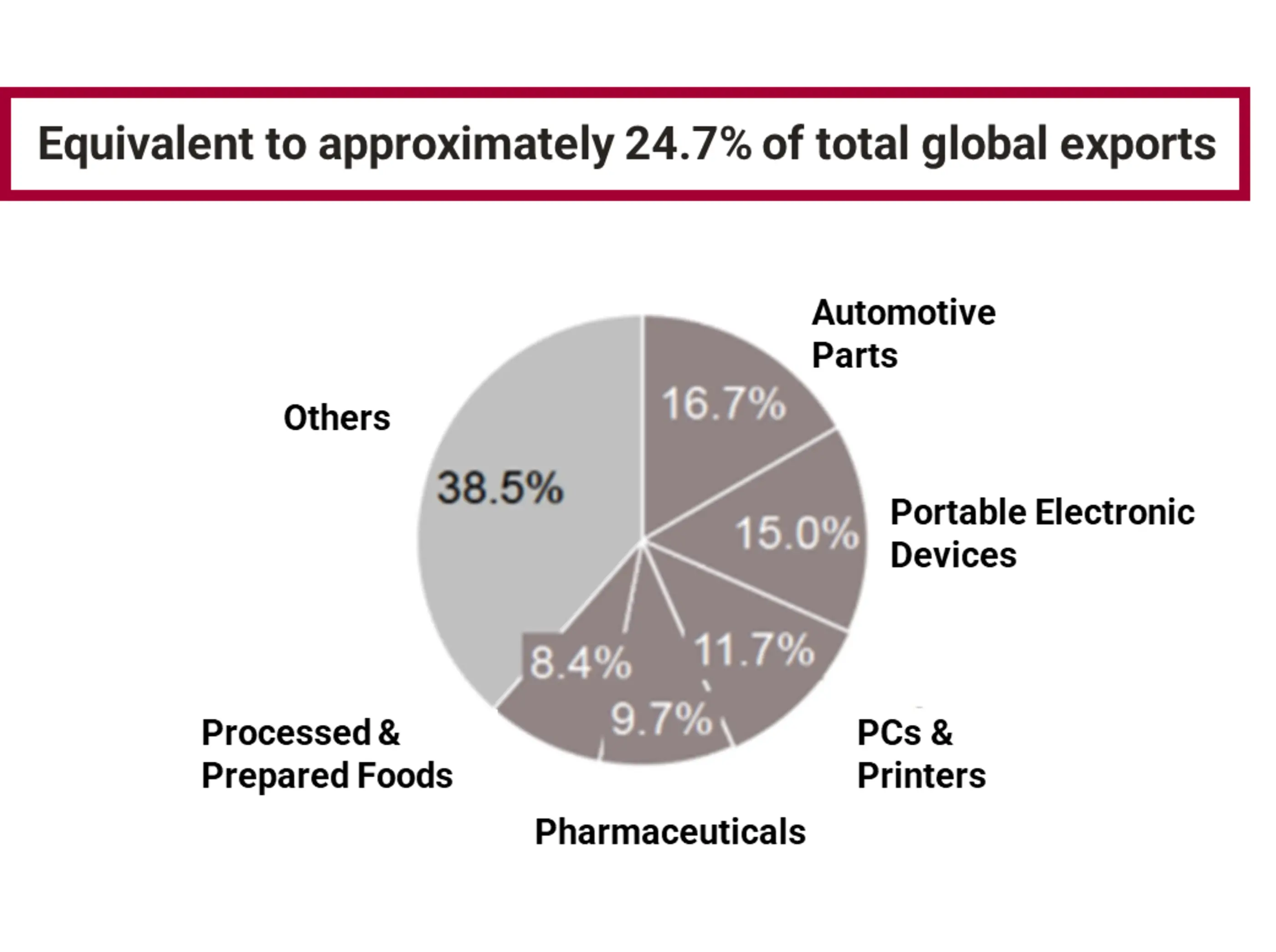

Counterfeiting has evolved into a $3.85 trillion USD global problem, impacting industrial and regulated markets worldwide. Imitation‑prone goods now represent nearly one quarter of global exports, making visual and digital anti‑counterfeiting measures such as holograms and QR codes no longer sufficient. Manufacturers now require physically non-replicable solutions to protect product integrity, compliance, and supply chains.

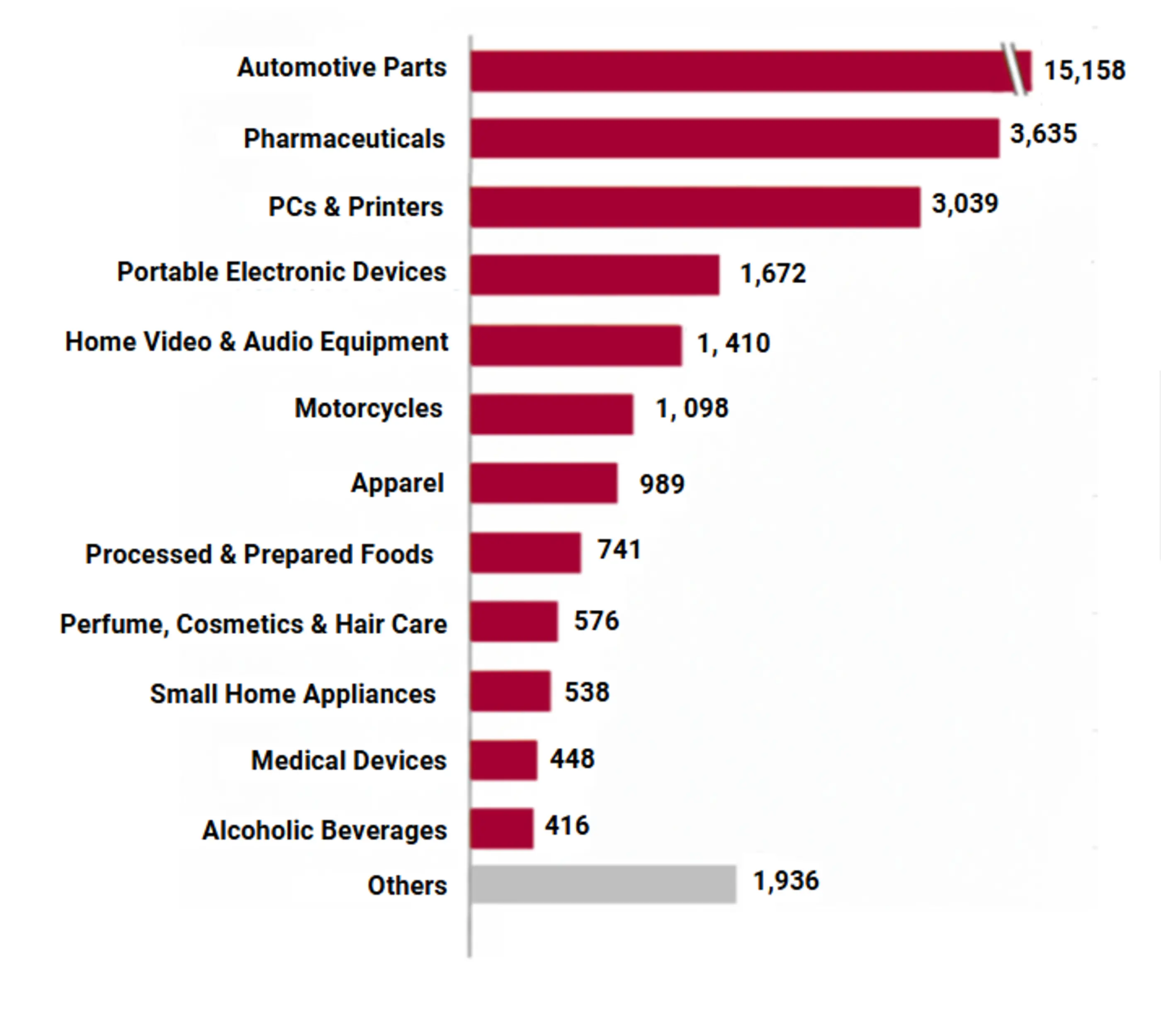

Estimated Damage from Counterfeiting to

Japanese Companies by Industry

(Unit: 100 million YEN)

Global Export Breakdown:

Imitation-Prone Industries

[Total: 3.85 Trillion USD]

Source: Japan Patent Office, "FY2021 Research Project on Estimated Counterfeit Damage by Industry in Japan – Final Report" (modified)

Developed by EUROKE-TECHNOPARTS, WEM® Technology is a patented anti-counterfeiting solution that authenticates products through micro-scale light-and-shadow patterns created by laser engraving. Authentication is based on a physically embedded three-dimensional structure, making replication is virtually impossible—delivering a level of security far beyond conventional technologies.

WEM® creates microscopic engravings—at the micrometer scale—directly on product surfaces or within molded components. The watermark is part of the material itself and cannot be removed, transferred, or copied like printed features. Authentication is based on optical behavior, providing durable, long‑term protection.

A proprietary algorithm analyzes the light‑and‑shadow patterns produced by the engraving to verify authenticity. Verification can be performed online or offline using smartphones, browser‑based tools, or dedicated inspection devices.

Engraving parameters and authentication workflows are optimized for material properties, product design, and production conditions. Multiple implementation options ensure seamless integration into existing manufacturing and quality‑control processes.

Enlarged View of WEM® Code — “GENUINE” Engraving

The dedicated authentication app analyzes the light-and-shadow patterns of the engraved watermark to decrypt the code, enabling highly reliable authenticity verification.

In industries such as automotive, electronics, and regulated manufacturing, authentication must withstand real-world conditions—not just visual inspection. Traditional technologies rely on copyable information or fragile components, creating gaps in security, reliability, and compliance.

WEM® Technology delivers a fundamentally different approach, embedding authentication directly into the physical structure of the product to ensure reliable verification across the entire lifecycle.

| Technology | Authentication Method | Security & Risk Profile | Design & Integration Flexibility | |

|---|---|---|---|---|

| Holograms | Visual inspection only | High risk of replication using widely available optical manufacturing tools | Limited flexibility; primarily cosmetic | |

| QR Codes | URL or database lookup (online required) | Vulnerable to copying, spoofing, and redirection to fraudulent sites | High information capacity, but security depends on external systems | |

| IC Tags (RFID/NFC) | Dedicated reader required | Susceptible to signal interference, data tampering, and environmental limitations (metal, moisture, heat) | Moderate flexibility; added cost and integration complexity | |

| WEM® Technology | Dedicated app with offline authentication | Physically non-replicable; authentication based on material structure, not copyable data | High flexibility across materials, designs, and manufacturing processes |

As counterfeiting methods advance, many traditional security technologies no longer provide reliable protection. Approaches based on visible features or digital identifiers are increasingly vulnerable to duplication or misuse.

Limited resistance to modern replication techniques

Vulnerable to duplication and URL manipulation

Cost and environmental constraints limit applicability

WEM® Technology supports multiple implementation methods, allowing authentication to be embedded in the most appropriate way based on product design, material, production volume, and regulatory requirements. Each approach is engineered to integrate seamlessly into existing manufacturing and quality-control processes.

Tamper-Evident Authentication

.Non-reusable stickers applied to products or packaging.

✔ Best for: Authenticity seals, certification labels

✔ Key benefit: Self-destructive design prevents removal or reuse

✔ Typical uses:: High-value goods, collectibles, premium packaging

Laser Engraved Authentication

Permanent engraving applied directly to metal or resin surfaces.

✔ Best for: Industrial components, automotive and electronic parts

✔ Key benefit: Embedded security without altering product design

✔ Typical uses: Parts requiring long-term traceability

Built-In Authentication at Scale

WEM® marks are engraved into molds and transferred during injection molding.

✔ Best for: High-volume production

✔ Key benefit: No post-processing required

✔ Typical uses: Plastic components, caps, housings

Getting started with WEM® Technology is a straightforward, collaborative process that allows you to find the best option to fit your product and manufacturing environment. The steps are as follows:

WEM® Technology is designed to work across a wide range of materials and manufacturing processes. Depending on your product and application, it can be implemented using:

This flexibility allows WEM® to integrate seamlessly into automotive, electronics, and regulated production environments.

Yes. WEM® authentication does not rely on a single feature or data point.

The dedicated authentication app analyzes multiple structural elements of the engraved mark, enabling reliable verification even if part of the watermark is worn, scratched, or partially damaged.

No, practical replication is not possible.

Each WEM® mark is generated using a client-specific proprietary algorithm, resulting in a unique three-dimensional structure that cannot be reverse-engineered. The authentication app is designed to recognize only genuine marks created through this algorithm.

No. One of the key advantages of WEM® Technology is that authentication can be performed 100% offline using the dedicated smartphone app. No server, cloud connection, or network access is required—making it well suited for factory floors, inspections, and field use.

WEM® Technology supports multiple authentication options to fit different operational environments and workflows. Authentication can be performed using the following devices: a dedicated smartphone app, a browser-based tool, or through integration with existing inspection systems and equipment.

This flexibility allows WEM® to align seamlessly with manufacturing, quality control, and compliance processes without disrupting current operations.

Complete the following fields with your information, as well as a short, detailed description of your request and a NAGASE Specialist will be in touch with you shortly.